버링 드릴 (플로우 드릴)

Burring Drill (Flowdrill) 버링 드릴 (플로우 드릴)

- 신공법 특수 드릴 : 플로우 드릴, 폼 드릴, 센터 드릴

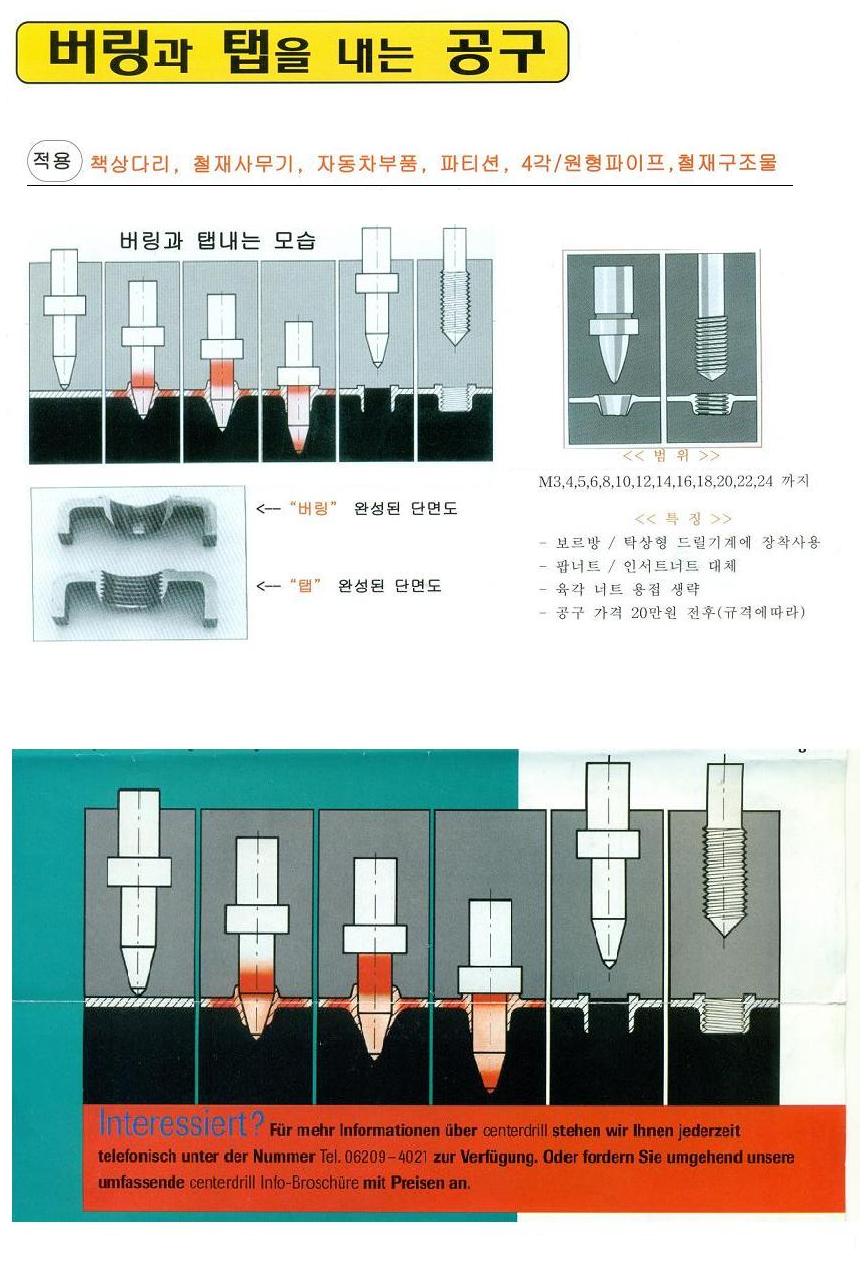

버링과 탭을 내는 공구

- 특징

-

- 보르방 / 탁상형 드릴기계에 장착 사용

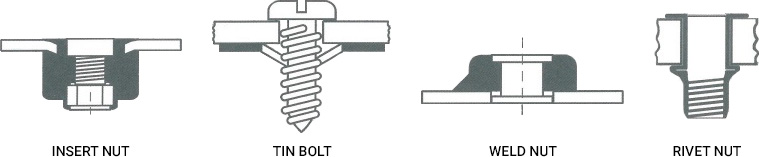

- 팝 너트 / 인서트 너트 대체

- 육각 너트 용접 생략

- 공구 가격 20만 원 전후 (규격에 따라)

- 적용

- 책상다리, 철재 사무기, 자동차 부품, 파티션, 4각/원형 파이프, 철재 구조물 등

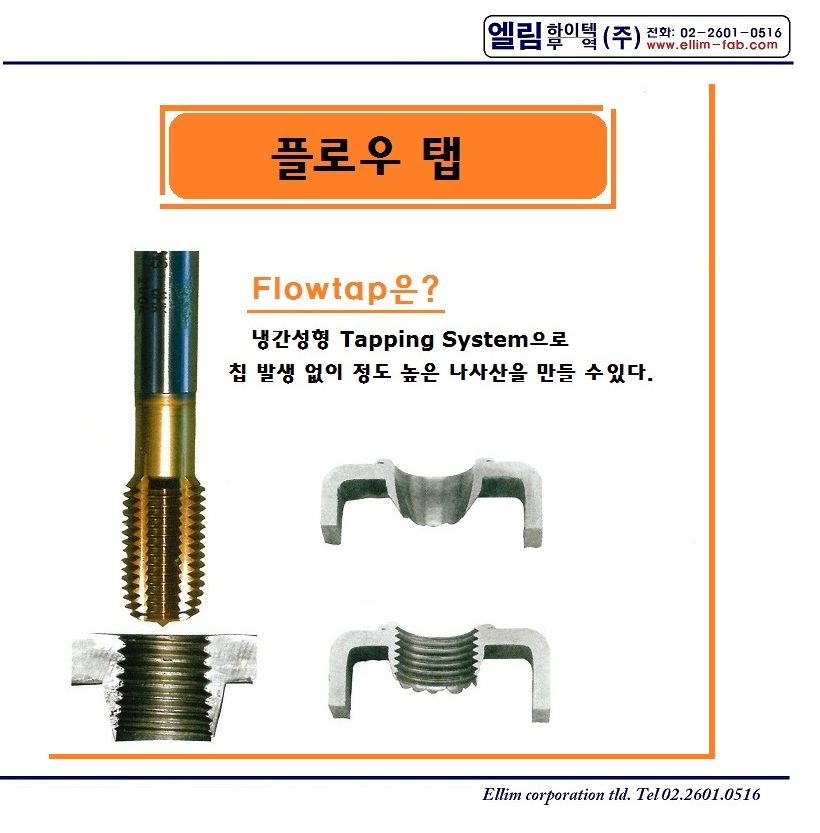

- Flowtap이란?

- 냉간성형 Tapping System으로 칩 발생 없이 정도 높은 나사산을 만들 수 있다.

- 범위

- M3, 4, 5, 6, 8, 10, 12, 14, 16, 18, 20, 22, 24까지

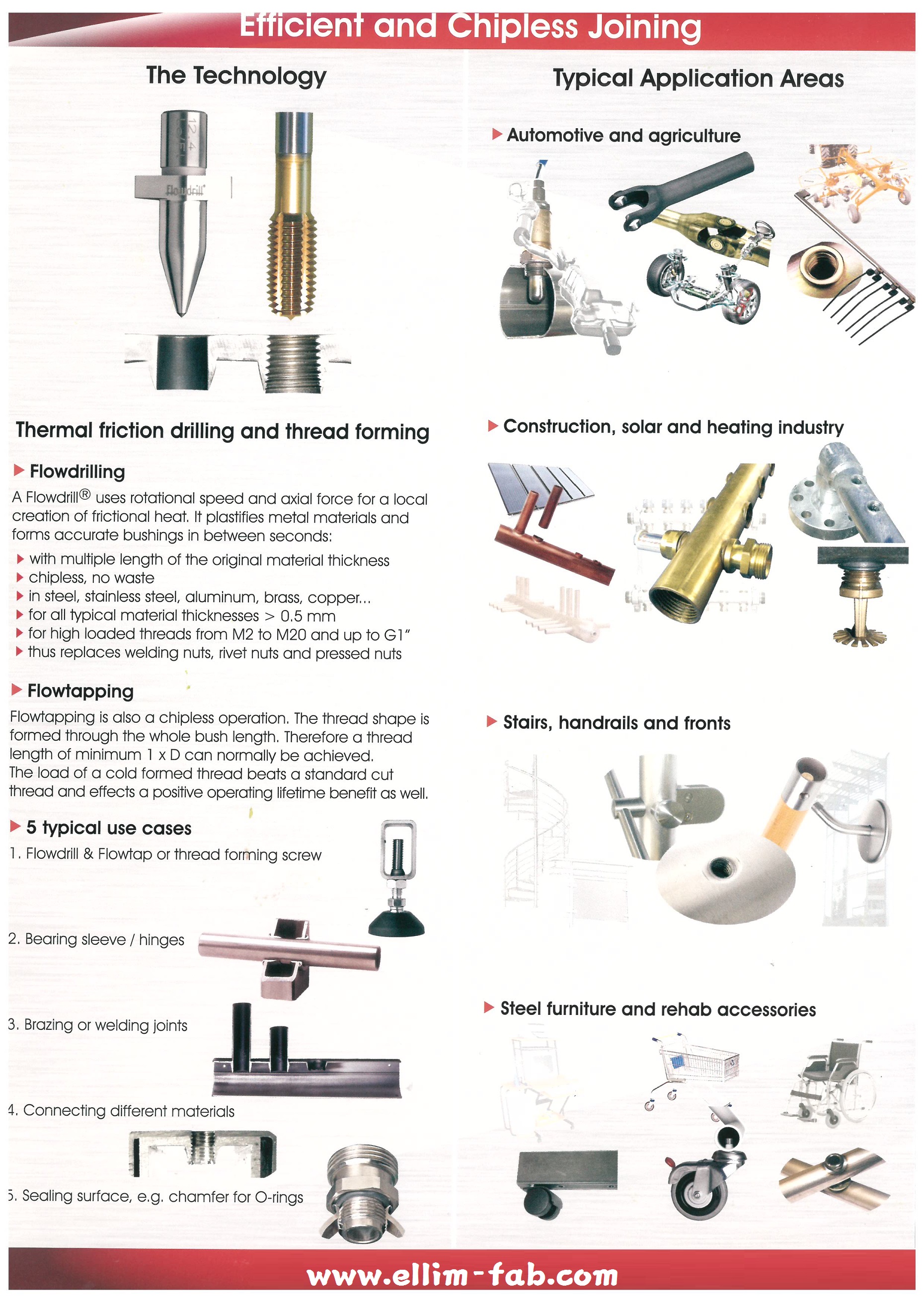

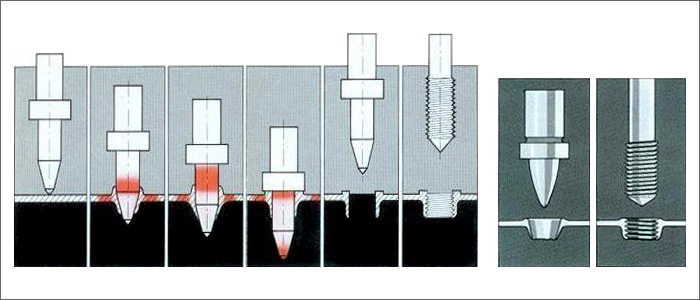

Thermal friction drilling and thread forming

- Flowdrilling

-

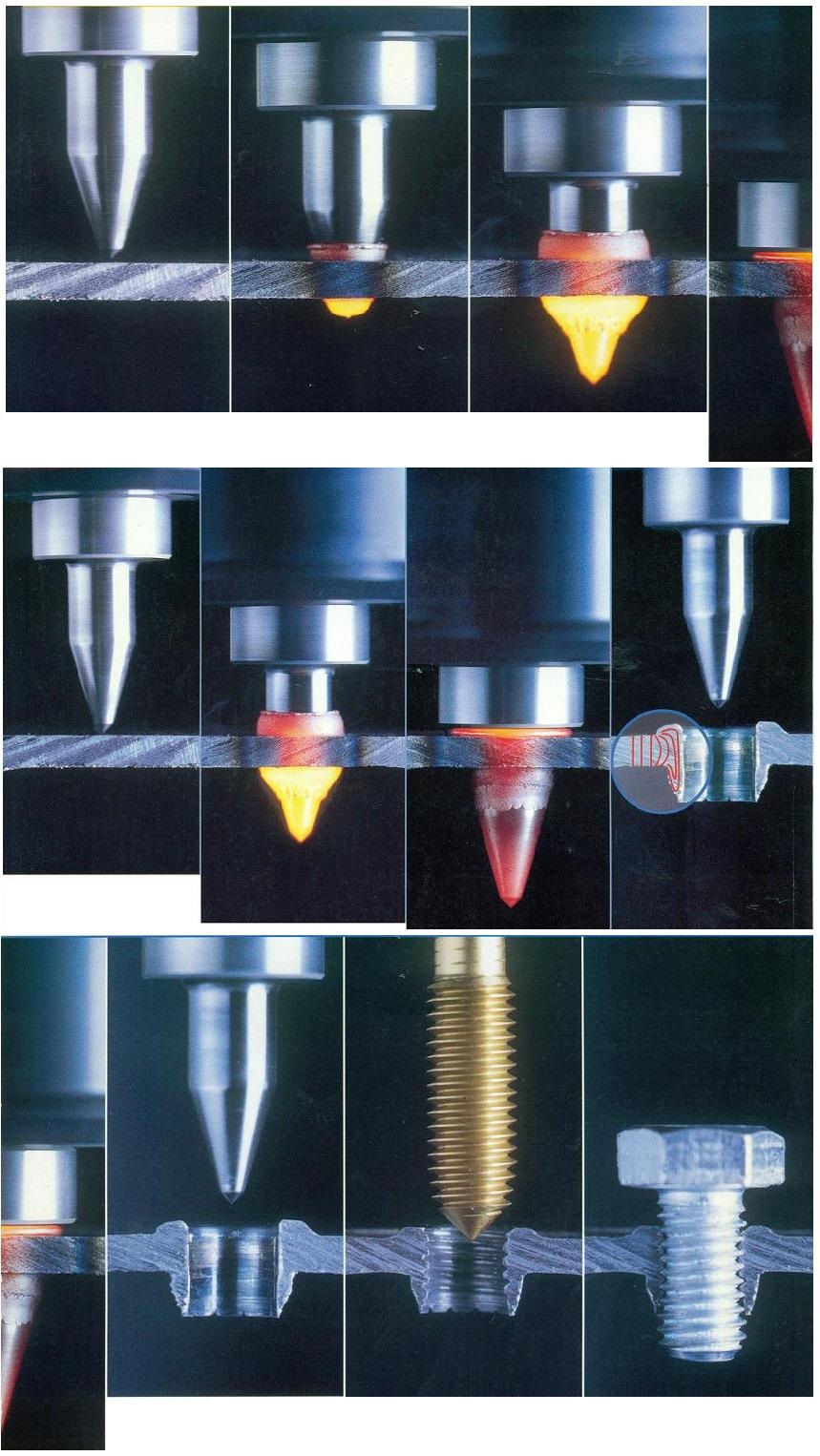

A Flowdrill® uses rotational speed and axial force for a local creation of frictional heat, it plastifies metal materials and forms accurate bushings in between seconds:

- with multiple length of the original material thickness

- chipless, no waste

- in steel, stainless steel, aluminum, brass, copper…

- for all typical material thicknesses > 0.5㎜

- for high loaded threads from M2 to M20 and up to G1"

- thus replaces welding nuts, rivet nuts and pressed nuts

- Flowtapping

- Flowtapping is also a chipless operation. The thread shape is formed through the whole bush length. Therefore a thread length of minimum 1×D can normally be achieved. The load of a cold formed thread beats a standard cut thread and effects a positive operating lifetime benefit as well.

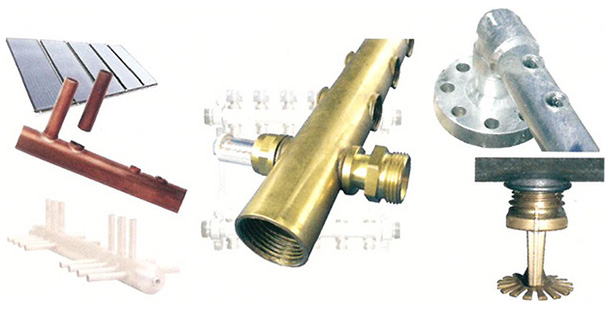

- 5 typical use cases

-

Flowdrill & Flowtap or thread forming screw

Sealing surface, e.g. chamfer for O-rings

Bearing sleeve / hinges

Brazing or welding joints

Connecting different materials

Typical Application Areas

취급품목

Advantages

- Increase of productivity

-

- chipless drilling and tapping

- no waste and removal costs

- no additional investment or storage costs

- reduction of operation steps

- no extraneous materials needed

- high process reliability

- solid carbide tools provide extra long lifetime

- Thread length with several times of material thickness

- Thread length with several times of material thickness

- Perfect flexibility - applicable on

-

- standard pillar machines

- CNC · automated machines

- our special designed mobile drilling unit

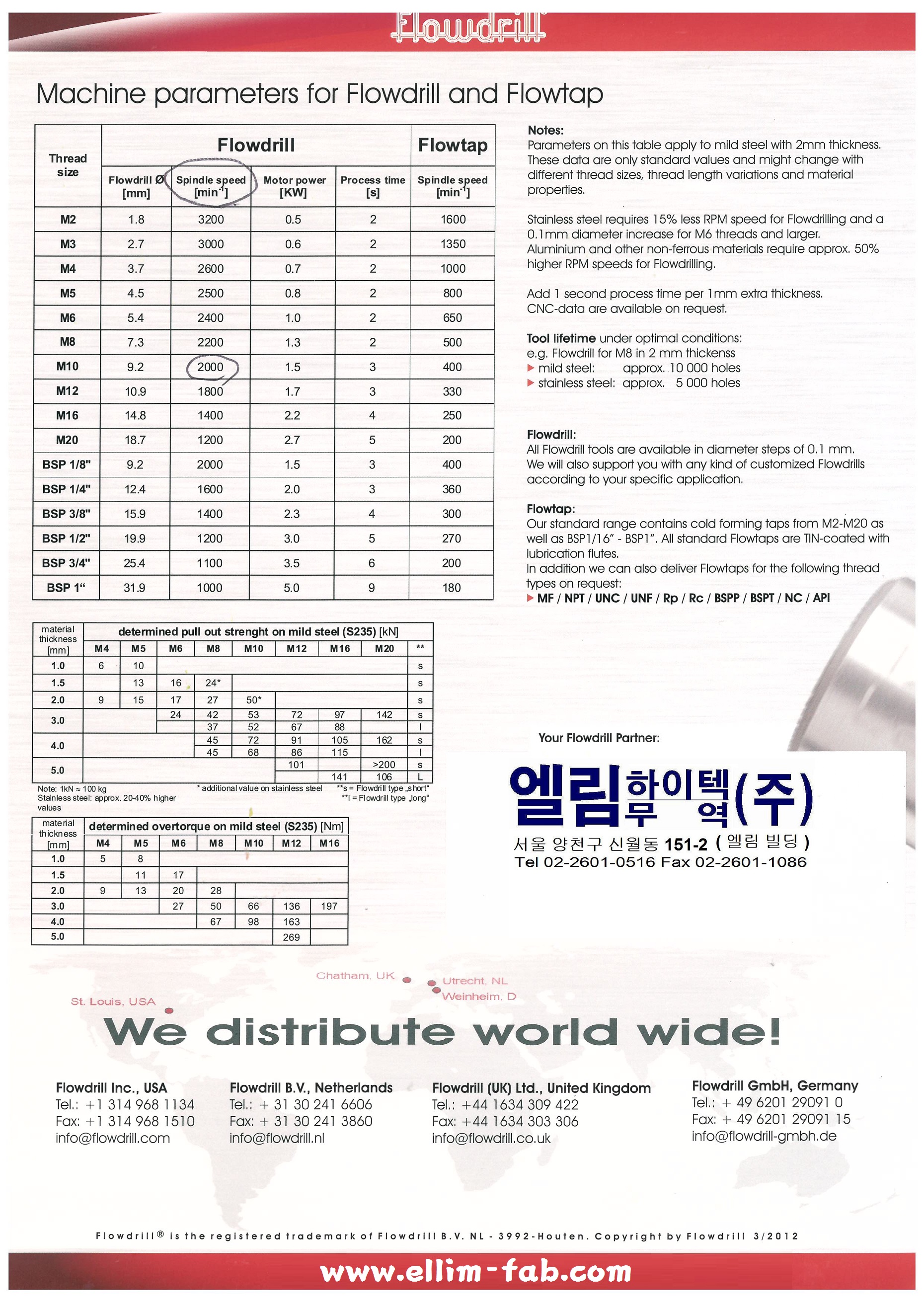

Machine parameters for Flowdrill and Flowtap

| Thread size | FLowdrill | Flowtap | |||

|---|---|---|---|---|---|

| Flowdrill Ø (㎜) | Spindle speed (min-1) | Motor power (㎾) | Process time (s) | Spindle speed (min-1) | |

| M2 | 1.8 | 3,200 | 0.5 | 2 | 1,600 |

| M3 | 2.7 | 3,000 | 0.6 | 2 | 1,350 |

| M4 | 3.7 | 2,600 | 0.7 | 2 | 1,000 |

| M5 | 4.5 | 2,500 | 0.8 | 2 | 800 |

| M6 | 5.4 | 2,400 | 1.0 | 2 | 650 |

| M8 | 7.3 | 2,200 | 1.3 | 2 | 500 |

| M10 | 9.2 | 2,000 | 1.5 | 3 | 400 |

| M12 | 10.9 | 1,800 | 1.7 | 3 | 330 |

| M16 | 14.8 | 1,400 | 2.2 | 4 | 250 |

| M20 | 18.7 | 1,200 | 2.7 | 5 | 200 |

| BSP 1/8" | 9.2 | 2,000 | 1.5 | 3 | 400 |

| BSP 1/4" | 12.4 | 1,600 | 2.0 | 3 | 360 |

| BSP 3/8" | 15.9 | 1,400 | 2.3 | 4 | 300 |

| BSP 1/2" | 19.9 | 1,200 | 3.0 | 5 | 270 |

| BSP 3/4" | 25.4 | 1,100 | 3.5 | 6 | 200 |

| BSP 1" | 31.9 | 1,000 | 5.0 | 9 | 180 |

| material thickness (㎜) | determined pull out strength on mild steel (S235) (kN) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | ** | |

| 1.0 | 6 | 10 | s | ||||||

| 1.5 | 13 | 16 | 24* | s | |||||

| 2.0 | 9 | 15 | 17 | 27 | 50* | s | |||

| 3.0 | 24 | 42 | 53 | 72 | 97 | 142 | s | ||

| 37 | 52 | 67 | 88 | l | |||||

| 4.0 | 45 | 72 | 91 | 105 | 162 | s | |||

| 45 | 68 | 86 | 115 | l | |||||

| 5.0 | 101 | >200 | s | ||||||

| 141 | 106 | L | |||||||

| material thickness (㎜) | determined overtorque on mild steel (S235) (kN) | ||||||

|---|---|---|---|---|---|---|---|

| M4 | M5 | M6 | M8 | M10 | M12 | M16 | |

| 1.0 | 5 | 8 | |||||

| 1.5 | 11 | 17 | |||||

| 2.0 | 9 | 13 | 20 | 28 | |||

| 3.0 | 27 | 50 | 66 | 136 | 197 | ||

| 4.0 | 67 | 98 | 163 | ||||

| 5.0 | 269 | ||||||

Notes:

Parameters on this table apply to mild steel with 2㎜ thickness. These data are only standard values and might change with different thread sizes, thread length variations and material properties.

Stainless steel requires 15% less RPM speed for Flowdrilling and a 0.1㎜ diameter increase for M6 threads and larger. Aluminium and other non-ferrous materials require approx. 50% higher RPM speeds for Flowdrilling.

Add 1 second process time per 1mm extra thickness. CNC-data are available on request.

- Tool lifetime under optimal conditions:

- e.g. Flowdrill for M8 in 2 mm thickenss

- mild steel: approx. 10 000 holes

- stainless steel: approx. 5000 holes

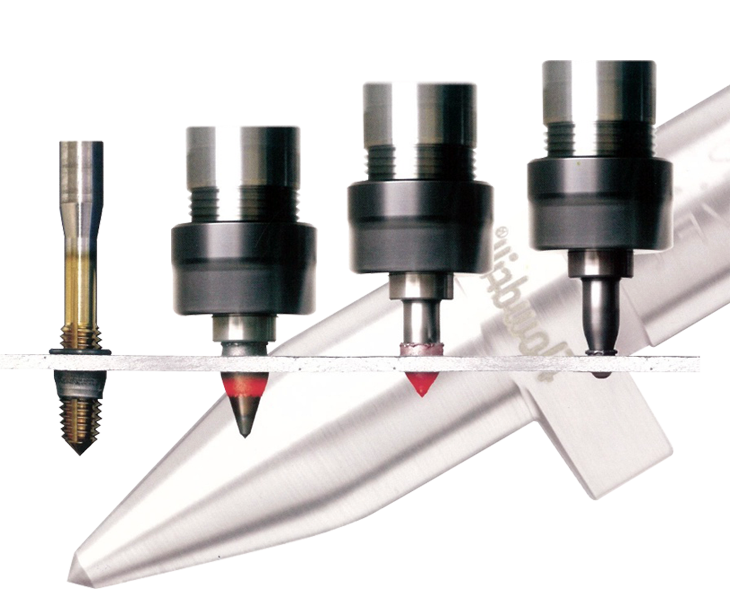

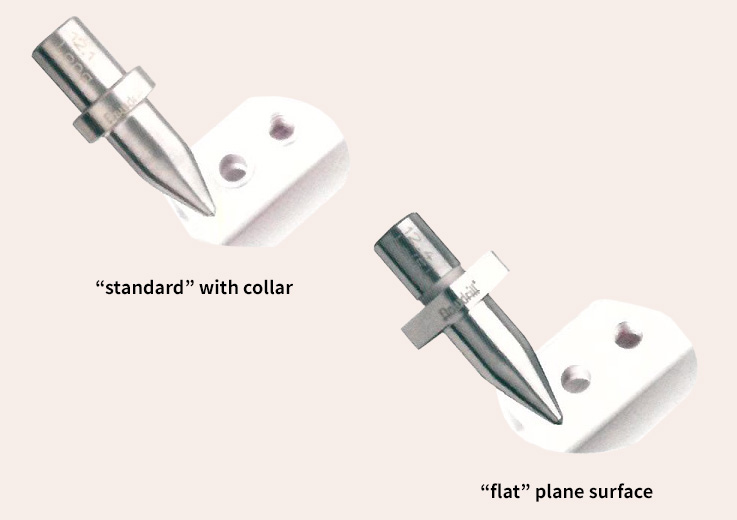

Flowdrill:

All Flowdrill tools are available in diameter steps of 0.1㎜. We will also support you with any kind of customized Flowdrills according to your specific application.

Flowtap:

Our standard range contains cold forming taps from M2-M20 as well as BSP1/16" . BSP1", All standard Flowtaps are TIN-coated with lubrication flutes. In addition we can also deliver Flowtaps for the following thread types on request:

MF / NPT / UNC / UNF / Rp / Rc / BSPP / BSPT / NC / API

버링 드릴 적용 사례 : 플로우 드릴, 폼 드릴